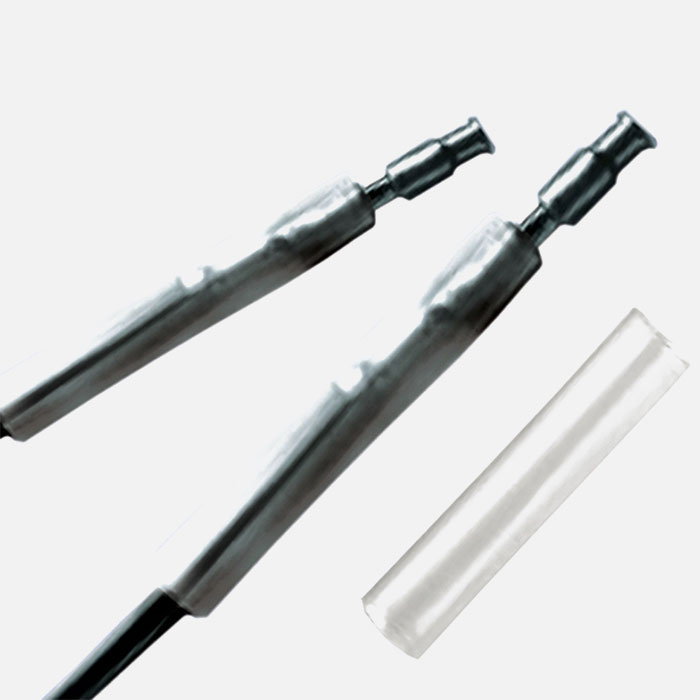

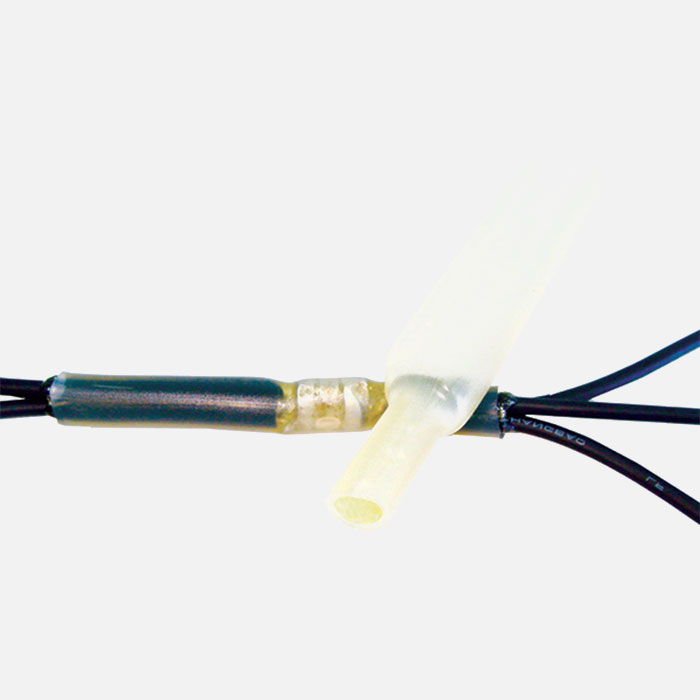

CYG-KYNAR(150) Heat Shrink Tubing

Category: Special Design Heat Shrink Tubing

Material:

Irradiation cross-linked modified polyolefin material

Shrink ratio:2: 1

Features:

• temperature, transparent, flame retardant;

• Soft (150 ℃) / semi-rigid (175 ℃);

• Operating temperature: -55 ℃ ~ 155 ℃ / -55 ℃ ~ 175 ℃;

• shrink temperature: 150 ℃ ~ 175 ℃;

• Soft type certification by UL224 150 ℃ 600V; • semi-rigid type of performance to meet the SAE-AMS-DTL23053 / 8 standards.

Application: The product has good heat resistance, wear resistance, chemical resistance to mechanical damage and corrosion, can be applied to those who may corrosive air, heat engine cycle, or mechanical stress adverse environmental; good flame performance, was also used in the automotive, aviation, boats, electronic equipment and other equipment wiring occasion, in addition, it is also well suited to distinguish between transparency and recognition encapsulated element encapsulation of electronic components.

| Size | Inner diameter | Dimension after full contraction | Supply length | ||||

|---|---|---|---|---|---|---|---|

| Minimum inner diameter before shrinkage | Maximum internal diameter after contraction | ||||||

| mm | Inch sizes | mm | Inch sizes | mm | Inch sizes | ||

| 3/64 | 1.2 | 0.046 | 0.6 | 0.023 | 0.25±0.05 | 0.010±0.02 | 200 |

| 1/16 | 1.6 | 0.063 | 0.8 | 0.031 | 0.25±0.05 | 0.010±0.02 | 200 |

| 3/32 | 2.4 | 0.093 | 1.2 | 0.046 | 0.25±0.05 | 0.010±0.02 | 200 |

| 1/8 | 3.2 | 0.125 | 1.6 | 0.062 | 0.25±0.05 | 0.010±0.02 | 200 |

| 3/16 | 4.8 | 0.187 | 2.4 | 0.093 | 0.25±0.05 | 0.010±0.02 | 100 |

| 1/4 | 6.4 | 0.250 | 3.2 | 0.125 | 0.33±0.05 | 0.013±0.02 | 100 |

| 3/8 | 9.5 | 0.375 | 4.8 | 0.187 | 0.33±0.05 | 0.013±0.02 | 100 |

| 1/2 | 12.7 | 0.500 | 6.4 | 0.250 | 0.33±0.05 | 0.013±0.02 | 100 |

| 3/4 | 19.1 | 0.750 | 9.5 | 0.375 | 0.43±0.08 | 0.017±0.03 | 50 |

| 1 | 25.4 | 1.000 | 12.7 | 0.500 | 0.43±0.08 | 0.019±0.03 | 50 |

| Item | Test method | Soft (150 ℃) Indicator | Semirigid(175℃) Indicator |

| Specific weight | ASTM D792 | ≤1.8g/cm3 | ≤1.8g/cm3 |

| Tensile strength | ASTM D2671 | ≥24.5MPa | ≥34.5MPa |

| Elongation at break | ASTM D2671 | ≥150% | ≥150% |

| Elongation at break after aging | 225°C/168h | ≥100% | ≥50% |

| Hot shock | 275°C/4h | Does not drip, does not crack | Does not drip, does not crack |

| Low temperature impact | -55°C/4h | No cracking | No cracking |

| Dielectric strength | ASTM D2671 | ≥15.7kV/mm | ≥31.5kV/mm |

| Volume short-death law | ASTM D257 | ≥1.0x1013Ω· cm | ≥1.0x1013Ω· cm |

| Combustion performance | UL224 | Through VW-1 | Through VW-1 |