CYG-MT(HX) High Flame Retardant Heat Shrinkable Marker Sleeves

Category: Marker Sleeve

Material: radiation cross-linked modified polyolefin material

Shrink ratio: 2: 1 3: 1

Features:

• products comply with UL224 and RoHS standards;

• Label performance to meet SAE-AMS-DTL-23053/5 requirements;

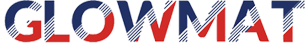

• Packaging diversity, to meet different customer requirements;

• sleeve may be provided directly to standard dot matrix printers and thermal transfer printers;

• sleeve may sided printing, readability;

• Standard color is white and yellow, other colors can be customized;

• have some dirt capacity, identify lasting.

Application:

CYG-MT(HX) low smoke, low toxicity flame retardant logo casing, has excellent resistance to ultraviolet radiation, it is to meet the manufacturer in an enclosed or unventilated environment for high-performance cable identification requirements and design. Can the ambient temperature is within the normal range -55 ℃ to 135 ℃. Label material identification performance meets the SAE-AS-81531MIL-STD-202F standard, the casing has a good organic solvent resistance and flame retardance.

CYG-MT(HX)(2:1)

| Specification | Dimension before shrinkage(mm) | Dimension before shrinkage(mm) | Continuous packing (m/plate) | Quantity per reel cassette packaging | ||

|---|---|---|---|---|---|---|

| Diameter(D) | Thickness(T) | Diameter(d) | Thickness(t) | |||

| Ф2.4 | ≥2.4 | 0.27±0.05 | ≤1.2 | 0.51±0.08 | 30 | 2000 |

| Ф3.2 | ≥3.2 | 0.27±0.05 | ≤1.6 | 0.51±0.08 | 30 | 2000 |

| Ф4.8 | ≥4.8 | 0.27±0.05 | ≤2.4 | 0.51±0.08 | 30 | 2000 |

| Ф6.4 | ≥6.4 | 0.32±0.06 | ≤3.2 | 0.64±0.08 | 30 | 1500 |

| Ф9.5 | ≥9.5 | 0.32±0.06 | ≤4.8 | 0.64±0.08 | 30 | 1500 |

| Ф12.7 | ≥12.7 | 0.32±0.06 | ≤6.4 | 0.64±0.08 | 30 | 500 |

| Ф19.1 | ≥19.1 | 0.36±0.06 | ≤9.5 | 0.76±0.08 | 30 | 500 |

| Ф25.4 | ≥25.4 | 0.45±0.08 | ≤12.7 | 0.89±0.08 | 30 | 250 |

| Ф38.1 | ≥38.1 | 0.50±0.08 | ≤19.1 | 1.02±0.15 | 30 | 250 |

| Ф50.8 | ≥50.8 | 0.58±0.08 | ≤25.4 | 1.14±0.18 | 30 | 250 |

Note: Other sizes and colors can be special order

CYG-MT(HX)(3:1)

| Contraction ratio | Dimension before shrinkage(mm) | Dimension after full contraction(mm) | Continuous packing (m/plate) | Quantity per reel cassette packaging | ||

|---|---|---|---|---|---|---|

| Diameter(D) | Thickness(T) | Diameter(d) | Thickness(t) | |||

| Ф2.4 | ≥2.4 | 0.22±0.05 | ≤0.8 | 0.53±0.08 | 30 | 2000 |

| Ф3.2 | ≥3.2 | 0.22±0.05 | ≤1.1 | 0.58±0.08 | 30 | 2000 |

| Ф4.8 | ≥4.8 | 0.22±0.05 | ≤1.6 | 0.58±0.08 | 30 | 2000 |

| Ф6.4 | ≥6.4 | 0.22±0.05 | ≤2.1 | 0.58±0.08 | 30 | 1500 |

| Ф9.5 | ≥9.5 | 0.20±0.05 | ≤3.2 | 0.61±0.08 | 30 | 1500 |

| Ф12.7 | ≥12.7 | 0.20±0.05 | ≤4.2 | 0.61±0.08 | 30 | 500 |

| Ф19.1 | ≥19.1 | 0.20±0.05 | ≤6.4 | 0.61±0.08 | 30 | 500 |

| Ф25.4 | ≥25.4 | 0.20±0.05 | ≤8.5 | 0.64±0.08 | 30 | 250 |

| Ф38.1 | ≥38.1 | 0.30±0.06 | ≤12.7 | 1.00±0.15 | 30 | 250 |

| Ф50.8 | ≥50.8 | 0.30±0.06 | ≤17.0 | 1.00±0.18 | 30 | 250 |

Note: Other sizes and colors can be special order

| Item | Test method | Indicator |

| Tensile strength | SAE-AMS-DTL-23053 | ≥10.3MPa |

| Elongation at break | SAE-AMS-DTL-23053 | ≥200% |

| Low temperature flexibility | SAE-AMS-DTL-23053.4.6.7 | -55℃±1℃,4h,No cracks |

| Hot Shock | SAE-AMS-DTL-23053.4.6.8 | 250℃±3℃,4h,No cracks, No dripping, No flow |

| Aging properties | SAE-AMS-DTL-23053.4.6.9 | 175℃±2℃,168h No damage (visually intuitive damage) |

| Tensile strength after aging | SAE-AMS-DTL-23053.4.6.13和ASTM D638 | ≥6.9MPa,23℃±2℃ |

| Elongation at break after aging | SAE-AMS-DTL-23053.4.6.13和ASTM D638 | ≥100%,23℃±2℃ |

| Color stability | SAE-AMS-DTL-23053.4.6.15 | 175℃±2℃,24h,by |

| Dielectric strength | SAE-AMS-DTL-23053.4.6.13AndASTM D2671 | ≥19.7kV/mm,23℃±2℃ |

| Volume resistivity | SAE-AMS-DTL-23053.4.6.13AndASTM D876 | ≥1.0x1014Ω· cm,500V(DC),60s |

| Flame retardant | SAE-AMS-DTL-23053.4.6.14AndASTM D2671 UL224 | Self-extinguishing within 60s, more than 25% of the iconic flag is damaged or burned, no dripping and a large area falling |

| Antibody solution performance | AE-AMS-DTL-23053.4.6.11 | No damage (visually intuitive damage) |

| Printing durability | SAE-AS-81531.4.6.2 | Eraser 50 times, the writing is clearly visible |

| Printing solvent resistance | MIL-STD-202G Method 215K | Eraser 10 times, the writing is clearly visible |