Heat Shrink Terminations and Joints Up to 36KV

Category: Cable accessories

Product manual

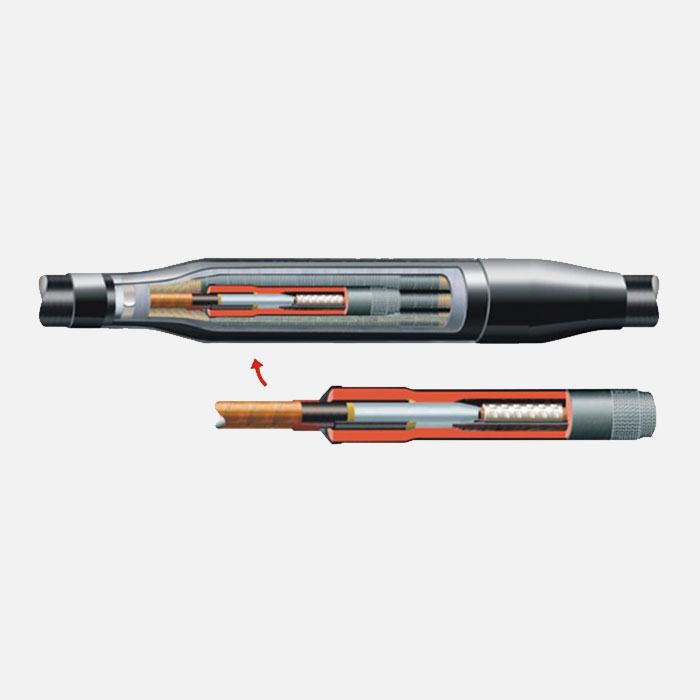

The heat-shrinkable terminations and joints are available for indoor& outdoor applications for single core and 3-core cables up to 36KV. The The heat-shrinkable cable accessories will provide excellent insulation, sealing and mechanical protection for power cables.

| Technical Performance | |||

| Items | 8.7/15KV | 12/24KV | 18/36KV |

| Indoor termincation | |||

| Ac withstand voltage rated | 39KV, 5 min no flashover, no strike | 81KV, 5 min no flashover, no strike | 117KV, 5 min no flashover, no strike |

| Partial discharge test | 13KV<5pc | 31KV<10pc | 45KV<10pc |

| Cyclic lad test | 3 cycles under 90-100 ℃,23KV | 3 cycles under 90-100 ℃,45KV | 3 cycles under 90-100 ℃65KV |

| Impulses voltage test | 95KV no flashover, no strike | 170KV no flashover, no strike | 200KV no flashover, no strike |

| 15min, 50HZ Voltage with standing test | 23KV, 15min no flashover, no strike | 45KV, 15min no flashover, no strike | 65KV, 15min no flashover, no strike |

| Humidity test | No any flashover, tracking, erosion or mechanical damage occur at 300h, 11KV | No any flashover, tracking, erosion or mechanical damage occur at 300h,21KV | No any flashover, tracking, erosion or mechanical damage occur at 300h,32.5KV |

| Outdoor termincation | |||

| Ac withstand voltage rated | 39KV, 5 min no flashover, no strike | 81KV, 5 min no flashover, no strike | 117KV, 5 min no flashover, no strike |

| Partial discharge test | 13KV<5pc | 31KV<10pc | 45KV<10pc |

| Cyclic lad test | 3 cycles under 90-100 ℃,23KV | 3 cycles under 90-100 ℃,45KV | 3 cycles under 90-100 ℃65KV |

| Impulses voltage test | 95KV no flashover, no strike | 170KV no flashover, no strike | 200KV no flashover, no strike |

| 15min, 50HZ Voltage with standing test | 23KV, 15min no flashover, no strike | 45KV, 15min no flashover, no strike | 65KV, 15min no flashover, no strike |

| Salt fog test | No any flashover, tracking, erosion or mechanical damage occur at 1000h, 11KV | No any flashover, tracking, erosion or mechanical damage occur at 1000h,21KV | No any flashover, tracking, erosion or mechanical damage occur at 1000h,32.5KV |

| Straight joint | |||

| Ac withstand voltage rated | 39KV, 5 min no flashover, no strike | 81KV, 5 min no flashover, no strike | 117KV, 5 min no flashover, no strike |

| Partial discharge test | 15KV<10pc | 31KV<10pc | 45KV<10pc |

| Cyclic lad test | 3 cycles under 90-100 ℃,23KV | 3 cycles under 90-100 ℃,45KV | 3 cycles under 90-100 ℃65KV |

| Impulses voltage test | 95KV no flashover, no strike | 170KV no flashover, no strike | 200KV no flashover, no strike |

| 15min, 50HZ Voltage with standing test | 23KV, 15min no flashover, no strike | 45KV, 15min no flashover, no strike | 65KV, 15min no flashover, no strike |

| Items | Requirements for Termination Kits for 8.7/15 KV Power Cable (As per Specification P-184: 86, IEC 60502-4 & IEEE Std. 48) |

| Indoor Termination | |

| Partial discharge test | 13kv<5pc |

| Power frequency voltage 1Min( dry) withstand test | No breakdown or flashover at 50KV |

| Power frequency voltage 6hrs(dry) withstand test | No breakdown or flashover at 35Kv |

| Lightning impulse voltage withstand test at 110 KV on both polarities (+ve & - ve) | No breakdown or flashover during 10 applications at 110Kv |

| DC withstand(dry) test for 15 min. | No breakdown or flashover at 75Kv DC |

| Radio influence voltage(RIV) test | RIV should not exceed 50uv when the samples is energized at 10Kv |

| Thermal short Circuit test | The specified current should flow for 2s through the termination (02-applications). The terminations shall not have any damage. |

| Humidity test | No any flashover, tracking, erosion or mechanical damage occur at 100h, 10.1KV |

| Cyclic Aging Test | As per Specification |

| Outdoor Termination | |

| Partial discharge test | 13kv<5pc |

| Power frequency voltage 1Min( dry) withstand test | No breakdown or flashover at 50KV |

| Power frequency voltage 10sec( wet) withstand test | No breakdown or flashover at 45KV for 10s |

| Power frequency voltage 6hrs(dry) withstand test | No breakdown or flashover at 35Kv |

| Lightning impulse voltage withstand test at 110Kv on both polarities (+ve & - ve) | No breakdown or flashover during 10 applications at 110Kv |

| DC withstand(dry) test for 15 min. | No breakdown or flashover at 75Kv DC |

| Radio influence voltage(RIV) test | RIV should not exceed 50uv when the samples is energized at 10Kv |

| Thermal short Circuit test | The specified current should flow for 2s through the termination (02-applications). The terminations shall not have any damage. |

| Tracking resistance test | The leakage current through of the surface of the terminations should not exceed 500mA during 101 operation of rain ON/OFF (10 Second ON & 20 Second OFF) |

| Salt fog test | No visible tracking or damage at 10.1Kv for 1 hour |

| Cyclic Aging Test | As per Specification |

| Straight Joints | |

| Partial discharge test | 15kv<10pc |

| AC withstand (dry) test at 39.5Kv for 5 min. | No breakdown or flashover at 39.5KV |

| AC withstand (dry) test at21.75Kv for 15 min. | No breakdown or flashover at 21.75 KV |

| Lightning impulse voltage withstand test at 95 KV | No breakdown or flashover during 10 applications for both +ve & -ve polarities at 95Kv |

| DC withstand(dry) test at 34.8 KV for 15 min. | No breakdown or flashover at 34.8Kv DC |

Thermal short Circuit test (conductor)

| The specified current should flow for 2s through the joint (Cable Conductor) (02-applications). The joint shall not have any sign of damage. |

| Thermal short Circuit test (screen) | The specified current should flow for 2s through the joint (Cable Screen) (02-applications). The joint shall not have any sign of damage. |