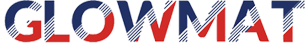

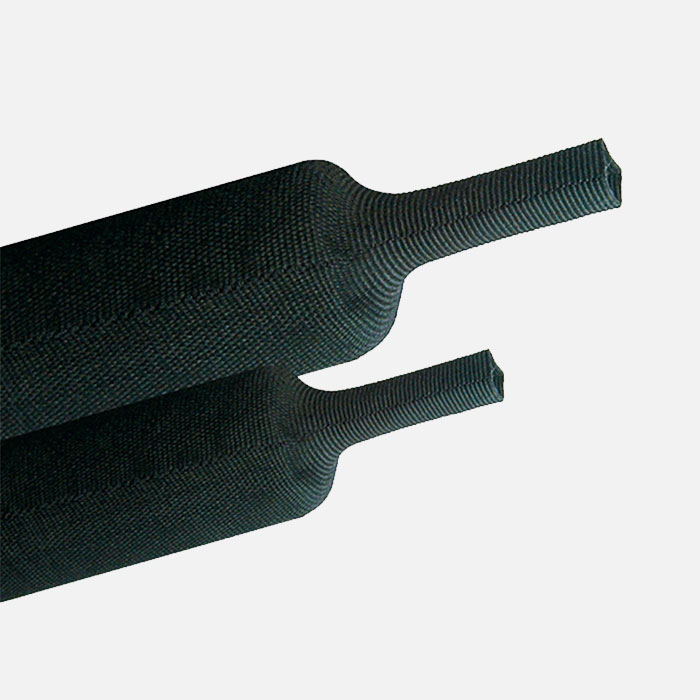

CYG-RSF Heat Shrink Fiber Sleeving

Category: Special Design Heat Shrink Tubing

Material: Radial: high-strength wear-resistant fiber

Weft: crosslinked modified polyolefin resin

Shrink ratio: 2: 1

Features:

• excellent softness, easy to install, wear-resistant, anti-vibration;

• Operating temperature: -40 ℃ ~ 125 ℃, shrink temperature: 110 ℃;

• Standard color: black;

• The maximum storage temperature: 60 ℃;

• Product Certification: UL product certification, certification number: E329207.

Applications: This product is designed for automotive rubber hoses, plastic pipes and wiring harness resistance to mechanical abrasion and design, but also has a good seismic noise reduction effect; its radial fiber material is extremely soft, easy to install, has excellent abrasion resistance performance, and good warm absorption.

| Specification | Before ContractionD(min.) | After Shrinkingd(max.) |

| CYG- HSF-12/6-B | ≥12 | ≤6 |

| CYG-HSF-20/10-B | ≥20 | ≤10 |

| CYG-HSF-30/15-B | ≥30 | ≤15 |

| CYG-HSF-40/20-B | ≥40 | ≤20 |

| CYG-HSF-50/25-B | ≥50 | ≤25 |

| CYG-HSF-60/30-B | ≥60 | ≤30 |

| CYG-HSF-70/35-B | ≥70 | ≤35 |

| Project | Test Methods | Index |

| Wear 200g load 144,000 cycles | 23℃ | Unaffected by rubber-coated tube wear |

| Heat aging properties | 125℃/168h | Under 23 ℃ condition is unaffected wear rubber-coated pipe fittings |

| Low temperature flexibility | Wrapped with 10 times the diameter of the mandrel/-40℃/4h | Uncracked |

| Cold impact test | -40℃下,200g weight (spherical bow) from 100mm freefall impact | Uncracked |

| Thermal Stress Test | Between -40 ℃ and 125 ℃, 100 cycles | Under 23 ℃ condition is unaffected wear rubber-coated pipe fittings |

| Solvent: antifreeze (50% ethylene glycol), mineral oil hydraulic oils, detergents, brake oil, unleaded gasoline and diesel, battery acid electrolyte | 23 ℃, 24h immersion | Under 23 ℃ condition is unaffected wear rubber-coated pipe fittings |